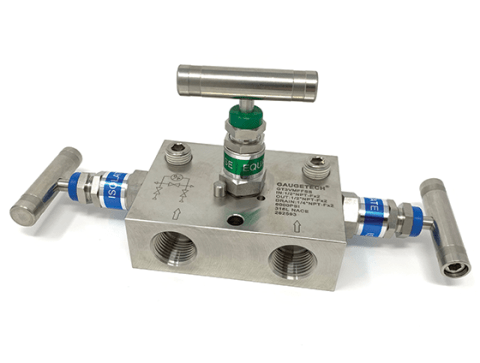

Hard seat, pipe to pipe

6,000 psi

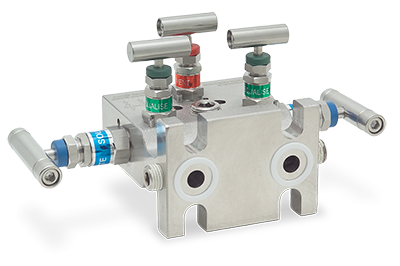

Gaugetech® three valve manifolds are supplied in 316L stainless steel and carbon steel with white zinc plate. GT3M series valves are produced in 1⁄2” NPT female-female, pipe to pipe threaded connections. The GT5M series are designed with a metal seat for severe working conditions.

FEATURES

- Non-rotating stem plug moves axially into and out of the seat without rotation to eliminate seat galling.

- The stem threads are rolled and lubricated to prevent galling and reduce operating torque.

- Valves are assembled with standard T-bar handles.

- All bonnets are assembled with a locking pin to prevent accidental removal while in service.

- Teflon® packing can be adjusted to increase valve life.

- Stem packing below the threads prevents lubricant washout and ensures no process contamination.

- The valves feature safety back seating to ensure a secondary stem seal.

- Dust caps are fitted to contain stem lubricant and prevent the ingress of contaminants.

- All valves are hydrostatically tested to 1.5 times maximum working pressure prior to shipment.

- The valves are Mill Test Traceable.

- Standard valve on manifold has a 4.8mm orifice size. Cv 0.52 MAX

- 316SS material traceable to NACE MR0175

- AB CRN# OC08236.2

- BC CRN# OC08236.21

- SK CRN# OC08236.23